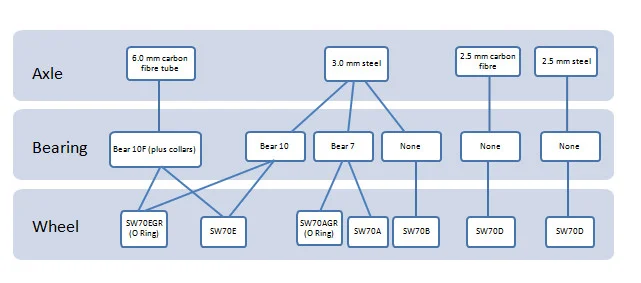

What choices do I have for Axles and Wheels? Our broad range allows for a lot of choices from basic wheel and axle up to carbon fibre with bearings and collars. The chart below outlines your options.

How do I put it all together?

Things to be aware of when chosing your materials

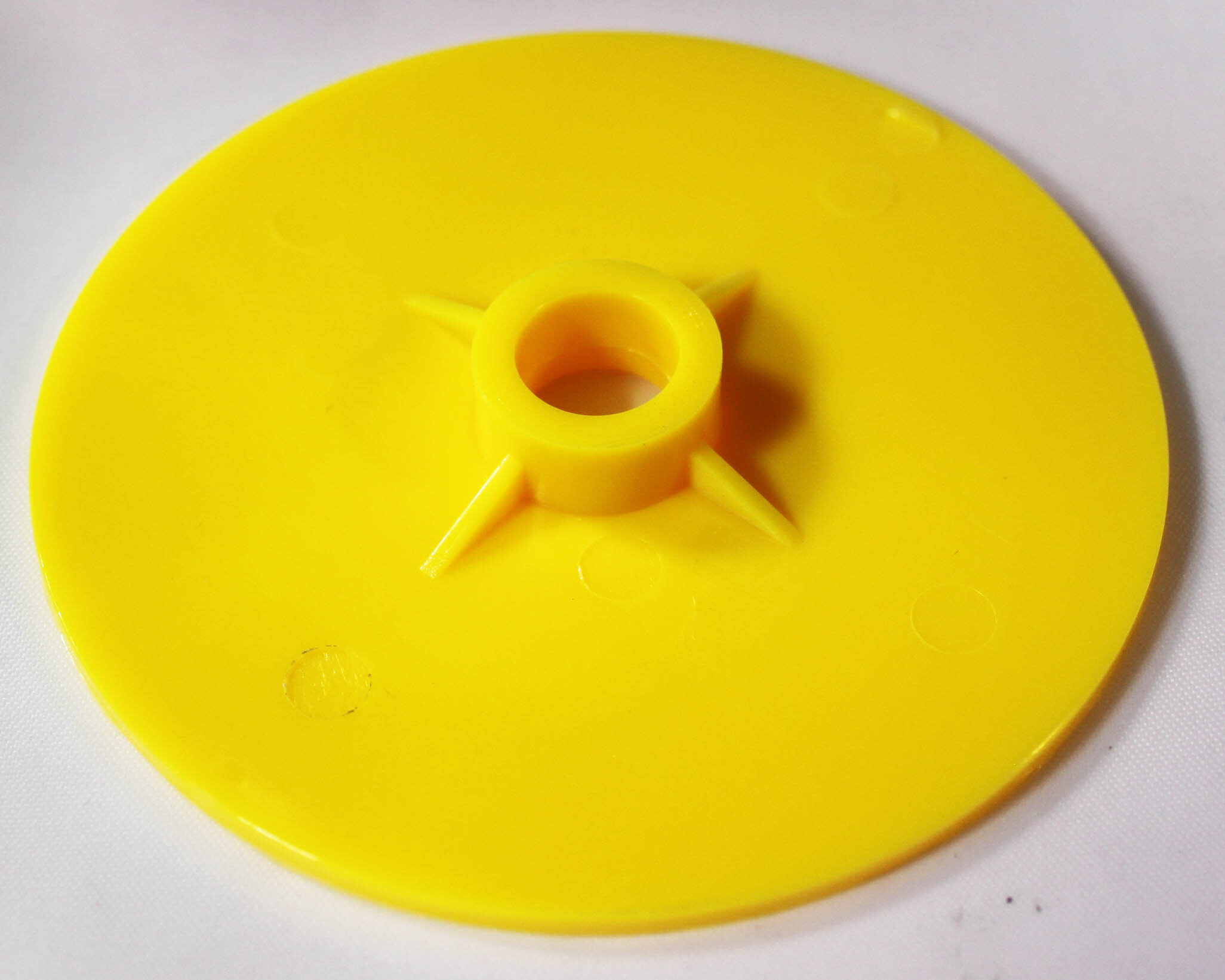

Three wheels are usually used without friction material to keep friction on the track to a minimum.

One driving wheel should have a “tyre” to increase friction on the track. If tyre material is chosen, then 4 of the same type of wheels (non-grooved) will be required. Otherwise an O-ring is used with a grooved wheel.

The wheel hub accepts two bearings side by side, and they are press-fitted in the hub. It is suggested that the bearings are glued in using Loctite 609 Adhesive.

The collars are used to retain wheels onto 6.0mm diameter axle. 2 collars are required per wheel, one on either side. A space of the thickness of a sheet of paper should be left, to allow the wheel / bearings to rotate freely. Collar ID = 6.2mm and is fixed to the axle by a small grub screw.

To provide lower friction between the axle and the guide tube, driveline bearings can be used with the larger diameter axle tube (GUIDY) – refer to the section on propeller shafts for the assembly drawing (2 per shaft).

If a smaller diameter wheel is required the 70mm wheels can be turned down on a lathe.

Frames

Construct your frame/chassis for your car using 6.0mm carbon fibre tubes.

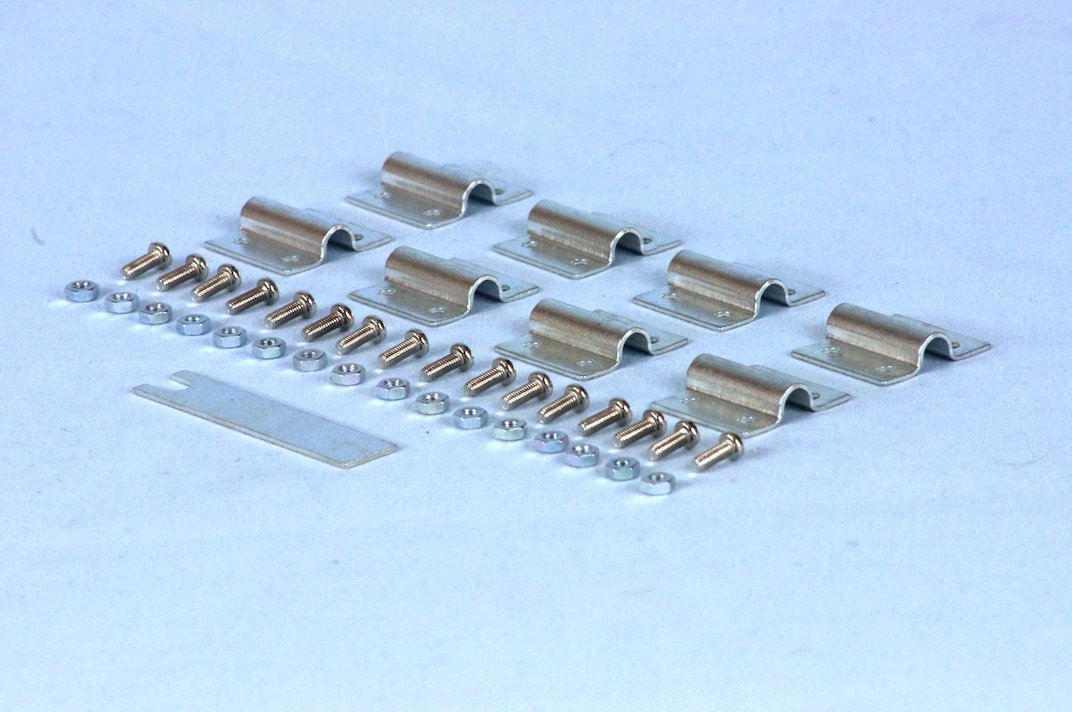

Axle Bracket Kit

Code: AXBKTK

AXLE BRACKET KIT

The Axle bracket kit consists of 8 axle brackets, nuts and bolts to assemble 6mm carbon fibre tubes into a rectangle.

Axle and Frame Kit

Code: AXFRK

The axle and frame kit consists of the Axle bracket kit and two 650mm long 6mm diameter carbon fibre tubes.

Guide Rollers

Code: GUIDEROLLER

25mm diameter x 9mm high.

Hole that will take 2 x 10mm flanged bearings with a 0.5mm thick washer between the bearings.

(NOTE: If the bearings in the guide rollers will be bolted, a half millimetre spacer may be required to avoid the bearings being crushed).

Click here to see our “Solar & Solar Challenge Catalogue” for full details and current prices.